HotVNA-S -- NA-SpecialX

HHF is leading in vector hot S-parameter measurements including the test-set design around 2.45 GHz. Our meanwhile established product HotVNA-S allows to perform calibrated complex S-parameter measurements with our VNA-modules. However, every hot-S-parameter configuration is costumer specified.

Often, you need to test your high power components under high power conditions! The drift of the phase is often a very identification of process control, management or detection for instabilities.

HotVNA-S is optimized to test microwave ovens as well as passive components like GHz-plasma, wave guides, cables, connectors, filters, antennas and more. Manufactures of these components can used HotVNA-S to perform accurate tests with typ. 6000W and much more.

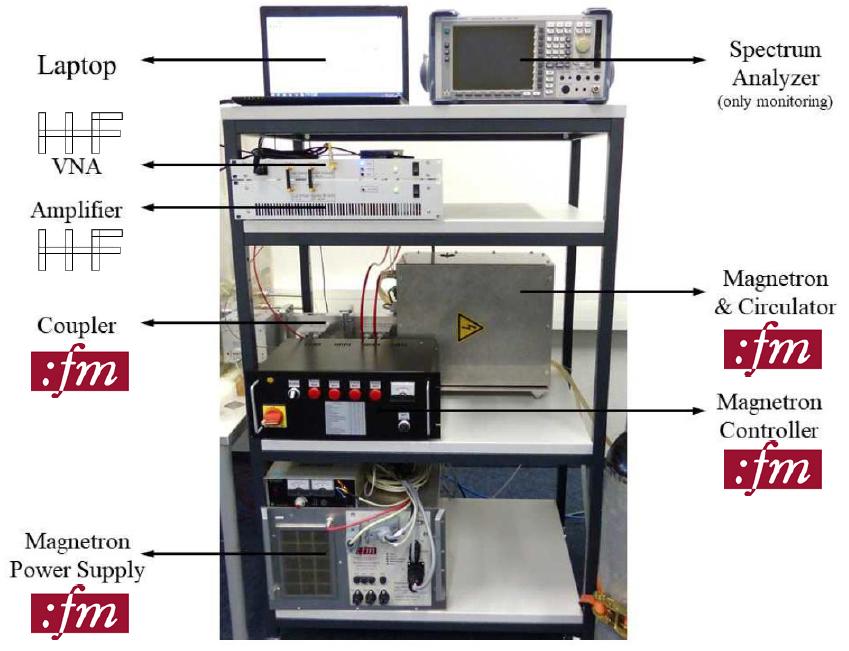

A typical configuration of a HotVNA-S-instrument for 6000 W and 2.45 GHz is shown in Fig. 1.

This VNA-hot-S-parameter measurement system consists out of a high power magnetron and other high power parts from the company Fricke und Mallah (:fm) and the 250W PA as well as the VNA-modules from HHF.

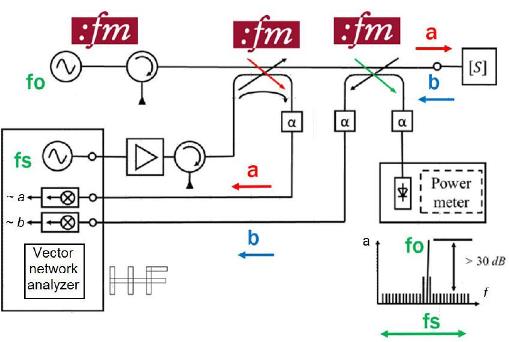

One full architecture of this HotVNA-S for one-port measurements is given in Fig. 2.

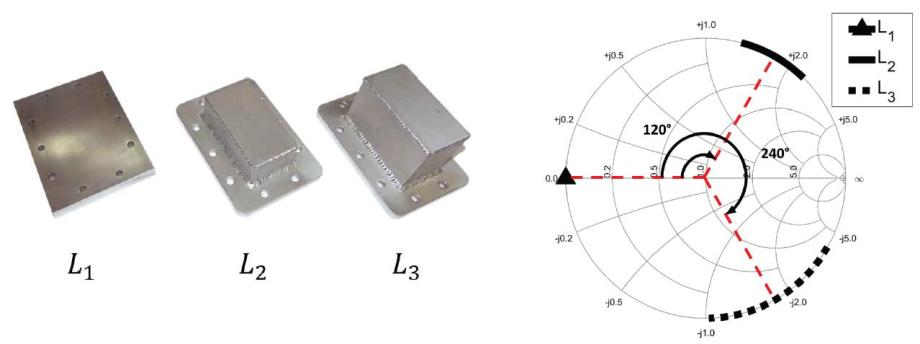

HHF sells this costumer defined measurement places with an open python-software. The included necessary calibration standards are shown in Fig. 3.

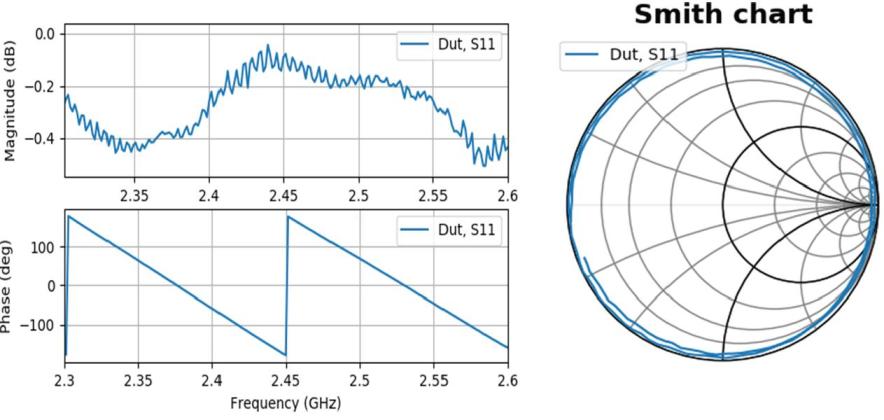

It is well known, that the calibration quality can be tested by the ripple test. Fig. 4 shows the very good results from the open python software.

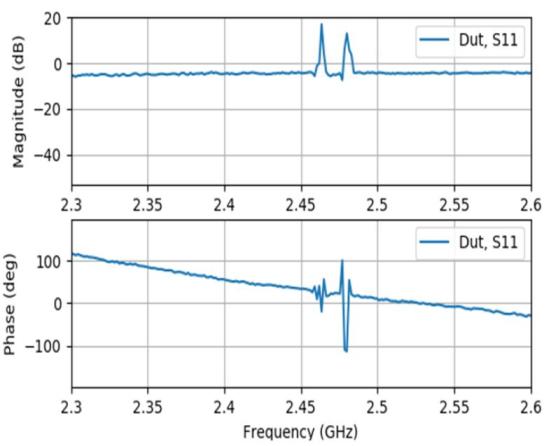

Hot-S-parameter measurements are necessary to characterize in the R+D-world the DUT in real conditions or to perform in the production world a perfect process control. Fig. 5 shows the very good results from the open python software including the measurement errors of the 6kW signal at the both sidebands of the receiver.

More information (operating manual, price, etc.) are available from Info@HHFT.de.